Fashion is a canvas, and textile printing is the brush that brings it to life. From the intricate patterns on a silk scarf to the bold graphics on a streetwear hoodie, textile printing plays a crucial role in defining styles and trends.

Over the years, this art form has evolved, embracing both traditional methods and cutting-edge technology. In this blog post, we delve into the diverse practices of textile printing, exploring its rich history, various techniques, and the innovations shaping its future.

The Role of Textile Printing in Fashion

Textile printing is more than just a technique; it’s a vital part of the fashion industry. It allows designers to translate their visions into tangible, wearable art.

Textile printing is more than just a technique; it’s a vital part of the fashion industry. It allows designers to translate their visions into tangible, wearable art.

Without textile printing, many iconic patterns and styles would not exist. Imagine the vibrant florals of Dolce & Gabbana, the intricate paisleys of Etro, or the bold geometrics of Missoni—all these designs rely heavily on advanced printing methods.

Beyond aesthetics, textile printing impacts functionality and sustainability in fashion. Designers use specific printing techniques to achieve desired effects on different fabrics, influencing everything from the durability of sportswear to the elegance of evening gowns.

This interplay between creativity and technology makes textile printing an indispensable tool in the fashion designer’s arsenal.

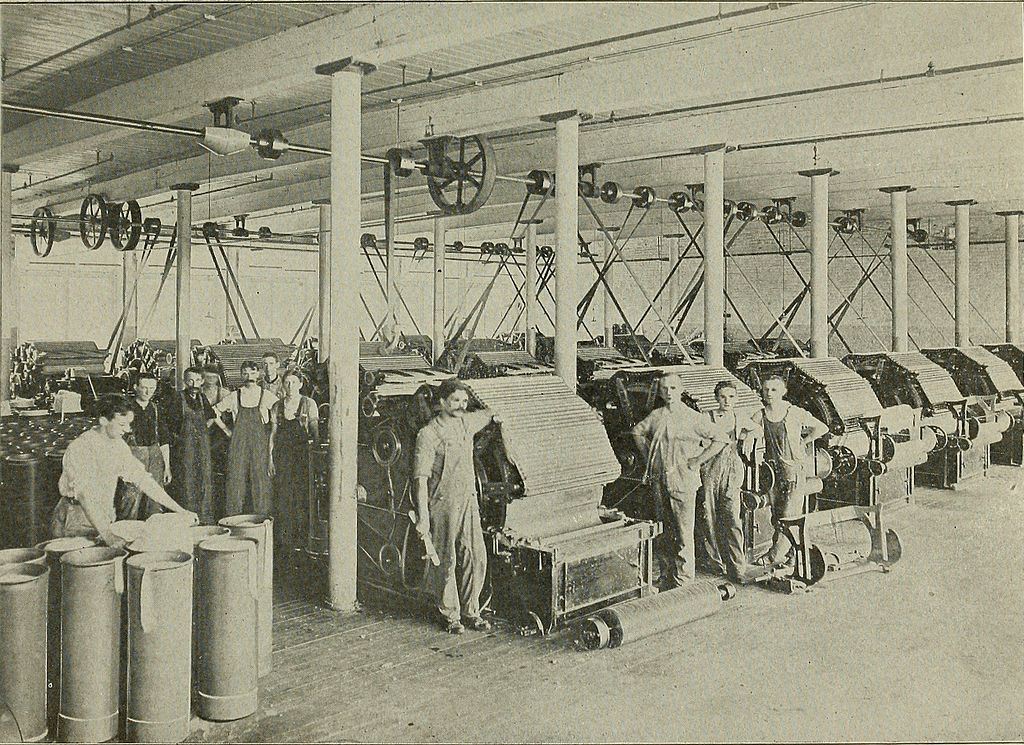

Historical Perspectives on Textile Printing

Artisans carved intricate patterns into wooden blocks, which were then dipped in dye and pressed onto fabric. This labor-intensive process produced beautiful, handcrafted textiles that were highly prized.

As time progressed, new technologies emerged, making textile printing more efficient and accessible. In the 18th century, the invention of roller printing revolutionized the industry. This method involved engraving designs onto copper rollers, allowing for continuous printing on fabric. It significantly increased production speed and opened up new possibilities for textile design.

Printing Methods: A Deep Dive

Block Printing

Block printing is one of the oldest and most traditional methods. It involves carving a design into a wooden block, applying dye to the block, and then pressing it onto the fabric.

This method is known for its artisanal quality and is often used for creating intricate patterns. Despite its labor-intensive nature, block printing remains popular for its unique, handcrafted aesthetic.

Direct-to-Film Printing

Direct-to-film (DTF) printing is an innovative technique that involves printing a design onto a special film, which is then transferred onto the fabric using heat and pressure. This method allows for detailed, multi-colored designs without the need for multiple screens or plates, making it an efficient and cost-effective option. DTF printers, such as the Prestige A4 Desktop printer can handle a variety of fabrics, from cotton to synthetic blends, providing flexibility for designers. Other modern printing machines like direct-to-garment (DTG) printers and rotary screen printers offer additional options, each with unique benefits and efficiencies.

Screen Printing

Screen printing is a versatile and widely used technique in the fashion industry. It involves creating a stencil, or “screen,” and using it to apply layers of ink on the fabric.

This method is ideal for bold, graphic designs and can be used on various materials, including cotton, polyester, and blends. Screen printing is favored for its durability and vibrant color output. However, it can be time-consuming and costly for designs with multiple colors.

Digital Printing

Digital printing represents the future of textile design. This method uses inkjet technology to print designs directly onto fabric. It offers unparalleled precision and the ability to reproduce complex patterns and photorealistic images.

Digital printing is highly efficient, allowing for short production runs and quick turnarounds. It also minimizes waste, making it an eco-friendly option. Brands like Burberry and Gucci have embraced digital printing to bring their intricate designs to life.

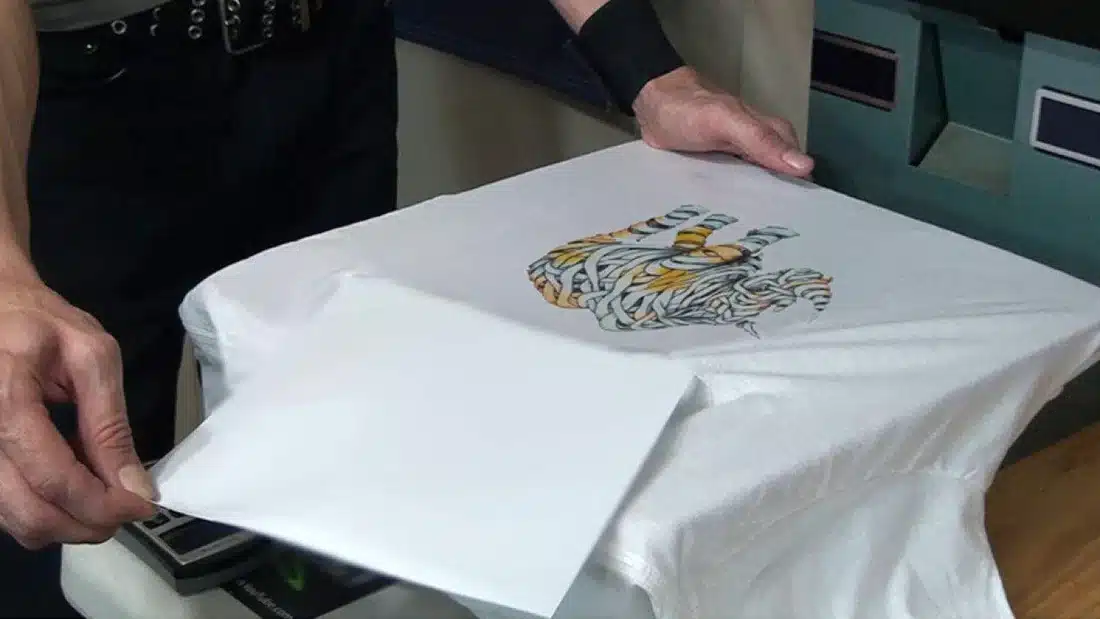

Heat Transfer Printing

Heat transfer printing involves transferring a printed design from paper to fabric using heat and pressure. This method is ideal for producing detailed images and is commonly used for custom apparel, such as t-shirts and sportswear.

While it offers excellent detail and color reproduction, heat transfer printing may not be as durable as other methods, particularly on heavily washed garments.

Sublimation Printing

Sublimation printing is a technique where dyes are converted into gas and then bonded with the fabric at a molecular level. This method is best suited for polyester fabrics and produces vibrant, long-lasting prints.

Sublimation is perfect for activewear, swimwear, and other performance apparel because the design becomes part of the fabric, ensuring it won’t fade or crack over time.

Trends and Innovations in Textile Printing

One notable trend is the rise of custom and on-demand printing. With digital technology, brands can now offer personalized products tailored to individual customer preferences. This approach reduces waste and aligns with the growing consumer demand for unique, sustainable fashion.

Case Studies: Innovative Uses of Textile Printing

Stella McCartney

Stella McCartney is renowned for her commitment to sustainability. Her collections often feature digitally printed fabrics made from organic cotton and recycled materials. By using eco-friendly printing methods, McCartney reduces her environmental footprint while delivering stunning, high-quality garments.

Alexander McQueen

The late Alexander McQueen was a master of textile innovation. His iconic Plato’s Atlantis collection showcased digital printing at its finest, with mesmerizing patterns inspired by nature. McQueen’s ability to blend technology and artistry set a new standard for fashion design.

Nike

Nike is a leader in performance apparel, utilizing advanced textile printing techniques to enhance functionality. The brand’s Dri-FIT technology, for example, incorporates sublimation printing to create moisture-wicking fabrics that keep athletes cool and comfortable. Nike’s commitment to innovation ensures their products not only look good but perform exceptionally well.

Conclusion

Textile printing is a fascinating blend of art and technology, transforming blank fabrics into stunning works of fashion. From ancient block printing to modern digital techniques, each method offers unique possibilities for designers. As the industry continues to innovate, we can expect even more exciting developments in textile printing.

The importance of diverse printing practices in fashion cannot be overstated. They allow designers to experiment, create, and bring their visions to life. As consumers, we benefit from the endless variety and creativity these techniques offer. Whether it’s a custom-printed t-shirt or a high-fashion gown, textile printing is an integral part of the fashion experience.