North Carolina experiences a range of weather conditions, including periods of freezing and thawing. These freeze-thaw cycles can significantly impact the durability of concrete structures, such as sidewalks, driveways, and buildings.

As temperatures fluctuate, water within the concrete expands and contracts, causing cracks, spalling, and damage to the internal structure. This damage not only affects the aesthetics of the concrete, but also reduces its strength and durability.

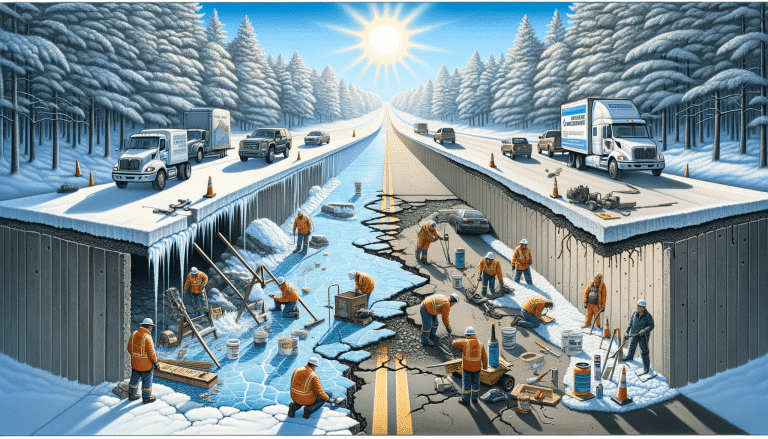

To address these issues, repair strategies have been developed to extend the life of concrete affected by freeze-thaw cycles. These methods focus on restoring the strength and durability of concrete, often by filling in cracks or addressing spalling and other signs of damage. Depending on the extent of the damage, various techniques may be employed by concrete repair services in North Carolina to ensure that the concrete remains safe and functional for use.

Understanding the impact of freeze-thaw cycles on concrete in North Carolina is vital for building and maintaining resilient infrastructure. Implementing appropriate repair strategies can help to prolong the service life of concrete structures and maintain their strength and durability in the face of harsh weather conditions.

Understanding the Freeze-Thaw Cycle in North Carolina

Science Behind Freeze-Thaw Damage

The term freeze-thaw cycle generally refers to the process when the air temperature falls low enough to freeze water (below 32°F/0°C), and then rises high enough to thaw (above 32°F/0°C). During this process, water entering concrete structures can freeze, expand, and then thaw, creating pressure that can cause damage to the concrete’s microstructure.

This damage results from a combination of factors, including water saturation within the concrete, the transition zone between the cement paste and aggregate particles, and the overall frost resistance of the material.

The deterioration mechanism typically involves water penetrating into the concrete’s porous microstructure and eventually reaching a point where it freezes and expands. This expansion creates tension within the concrete, which can lead to the formation of cracks and microcracks over time.

Impact on Concrete Structures and Pavements

The freeze-thaw cycle can cause significant damage to concrete structures and pavements, impacting their durability and service life. Common manifestations of freeze-thaw damage include scaling, or the flaking away of the concrete surface, and deterioration of the concrete’s microstructure.

Some factors that contribute to the extent of freeze-thaw damage on concrete structures and pavements include:

- Water saturation: The more water absorbed into the concrete, the higher the likelihood of damage occurring.

- Frost resistance: A material with high frost resistance will be less susceptible to freeze-thaw damage.

- Transition zone: The bonding strength between cement paste and aggregate particles can influence the durability of the concrete structure.

- Microstructure: Factors affecting the concrete’s microstructure, such as air entrainment, can impact its susceptibility to freeze-thaw damage.

Structures and pavements suffering from repeated freeze-thaw cycles often require extensive repairs or replacement to maintain their service life and functionality. By understanding the science behind freeze-thaw damage and its impact on concrete structures, engineers and construction professionals can develop repair strategies and choose materials with greater frost resistance to minimize the negative effects of these cycles in North Carolina.

Effective Repair and Mitigation Strategies

Materials and Technologies for Enhanced Durability

One approach involves using supplementary cementitious materials (SCMs) like fly ash, which can improve the mechanical properties and pore structure of concrete. This can help reduce the water absorption rate and make the concrete less susceptible to freeze-thaw damage.

Air-entraining agents can also be added to concrete mixes to create tiny air bubbles within the concrete’s structure. This increases the air content, helping to alleviate pressure from freezing and thawing cycles, ultimately reducing damage risks.

Innovative materials like nanoparticles have shown promise in enhancing concrete durability, as they can modify the water absorption and transport properties of the concrete matrix. Similarly, using fiber reinforcement in concrete can also contribute to improving the mechanical performance and durability of structures exposed to freeze-thaw cycles.

Additionally, implementing phase change materials (PCMs) and super absorbent polymers (SAPs) have shown potential in mitigating the effects of freeze-thaw cycles. PCMs can store and release heat, helping to regulate temperature fluctuations, while SAPs absorb water, reducing the concrete’s water content and freezing damage.

Best Practices in Concrete Repair

First, it is essential to determine the extent of the damage and the underlying damage mechanism, which may involve the evaluation of environmental factors, deicing chemicals, and mechanical and transport properties of the concrete.

Once the damage mechanism is identified, suitable repair strategies can be selected. These may involve the removal of calcium chloride as a deicing agent, as it is known to accelerate freeze-thaw damage, and replacing it with other deicing salts or less harmful deicing chemicals.

When repairing the concrete itself, consideration should be given to the use of Portland cement concrete mixed with SCMs. This mix can improve concrete durability and reduce the risk of damage from freeze-thaw cycles. Curing conditions should also be carefully monitored, as incorrect curing can negatively affect the concrete’s mechanical properties, resistivity, and hydration products.

Finally, if a concrete repair is necessary, incorporating fibers or other reinforcements into the repair materials can be beneficial, as they can enhance the mechanical and structural performance of the repair and help prevent further freeze-thaw damage.

By considering these materials, technologies, and best practices, concrete structures exposed to North Carolina’s freeze-thaw cycles can be more effectively repaired and better protected against future damage.

In Conclusion

The freeze-thaw cycle in North Carolina has a significant impact on the long-term performance of concrete structures. One of the key factors contributing to the deterioration of concrete is the repetitive expansion and contraction due to freezing and thawing of water within the concrete pores. This cycle can lead to D-cracking, which adversely affects the durability and service life of concrete structures in cold regions.

To mitigate the negative effects of freeze-thaw cycles, several repair strategies have been developed:

- Materials selection: Implementing high-quality materials that are less susceptible to freeze-thaw damage can help improve the overall durability of concrete structures. For example, using aggregates with low water absorption rates can minimize the amount of water that can freeze within the concrete.

- Air-entraining admixtures: These admixtures introduce microscopic air bubbles into the concrete mixture that help to accommodate the expansions and contractions during the freeze-thaw cycle. The use of air-entraining admixtures has been shown to significantly improve the freeze-thaw durability of concrete.

- Protective coatings: Applying protective coatings to the surface of concrete structures can help reduce the amount of water that penetrates into the concrete, thereby decreasing the likelihood of freeze-thaw related damage.

Regular inspections and proactive maintenance tasks are crucial in ensuring the longevity of concrete structures exposed to freeze-thaw cycles. Additionally, effective drainage systems should be implemented to minimize the accumulation of water within the concrete, thus reducing the risk of freeze-thaw damage.

Incorporating the aforementioned repair strategies can help preserve the integrity and extend the service life of concrete structures in North Carolina, where freeze-thaw cycles pose a significant challenge. Engineers and construction professionals must work together to continually innovate and develop new techniques to improve the durability and performance of concrete in cold climates.