As a trusted HVAC Houston company and its surrounding areas, Texas Strong Mechanical understands the importance of a high-reliability and energy-efficient heat pump system, especially when the days in Houston are really hot.

Whether you are a homeowner or a business owner, a breakdown of your heat pump is certain to take your comfort of afternoon evening to the roasting point.

This is why we have prepared this complete guide to heat pump problem detection and maintenance that will help you find out what is the cause of your complaints and guarantee that it will remain cold during the hottest summer months.

Understanding the Mechanism of a Heat Pump

During the cooling process, the pump sucks heat from the indoor air and expels it to the outside leading to the freshness of indoor air. The changeover is the opposite procedure whereby the heat pump now extracts heat from the outdoor air and brings it inside.

Multi-functionality becomes the core reason behind the swift rise in popularity of heat pumps in the Houston area where the weather swings from severe heat to a mild winter. After all, there are a lot of different parts connected in this complex system and this could also mean a higher risk of a faulty heat pump that won’t cool well.

Common Causes of a Heat Pump Cooling Failure

1. Thermostat Issues

The most common and easiest place to begin is your thermostat. Be sure that it is in “cool” mode and that the selected temperature is lower than the existing indoor. If the thermostat is faulty or miscalibrated, it will likely not relay the proper signals to the heat pump to initiate a cooling cycle.

2. Dirty Air Filters

Blocked or dirty air filters will limit airflow, resulting in your heat pump working harder to circulate the air. This enhanced pressure may cause a decrease in cooling capacity and efficiency level. Establish a routine to change and put in new filters every 1-3 months, or as recommended by your air filter manufacturer.

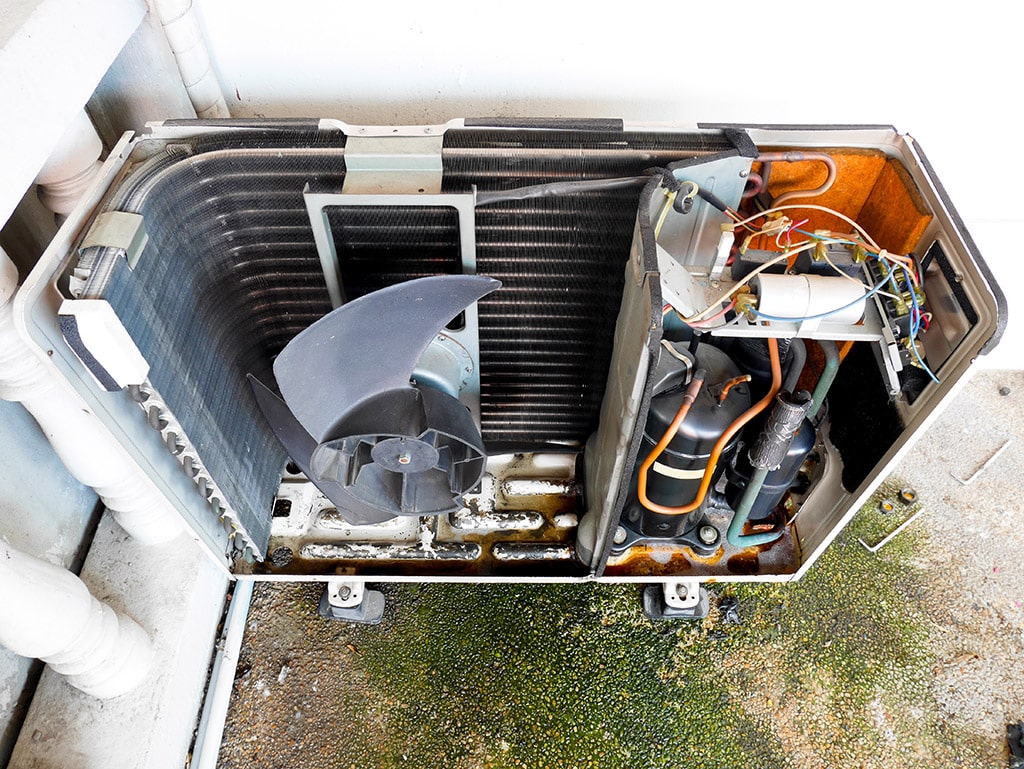

3. Outdoor Unit Obstructions

The outdoor portion of your heat pump is responsible for removing the heat against which your indoor space is protected. If there is trash, weeds, or any other barrier obstructing the flow of that heat out of the system, the system will struggle to cope with the heat.

4. Refrigerant Leaks

The heat pump operation critically depends on the right refrigerator level. If the refrigerant is leaking, the level would be decreased, therefore, the heat pump would not be able to extract and transfer heat effectively. Repairs of the refrigerant are beyond the scope and need an experienced HVAC person.

5. Electrical Issues

Heat pumps utilize the following electrical parts: compressor, blower, and control board. If any of these components fail or there is a lack of power to them, cooling efficiency will not be possible.

6. Reversing Valve Failure

This reversing valve component is quite important to the heat pump so that it can switch between heating and cooling modes. If the reverse valve fails to function effectively through malfunction or it becomes stuck, the whole refrigerator system might not circulate the refrigerant ideally leading to cooling failure.

When to Call the Professionals at Texas Strong Mechanical

1. Refrigerant Levels

If the problem is related to the refrigerant level, you may need to call our air conditioning specialist. Working with refrigerants demands qualification and certification skills because of the environmental and security laws. Refilling or repairing the refrigerant system yourself is risky and may lead to additional damage to your heat pump.

2. Electrical Components

We don’t advise working with electrical components like capacitors, contactors, or control panels. Attempting DIY repairs on this kind of parts can be hazardous, and could cause further damage to your heat pump’s electrical system.

3. Ice or Frost Build-Up

Frost or ice build-up on your heat pump is a visible indicator of internal issues. That’s why it is a good idea to hire a professional to check. This may refer to leaks, refrigerant flow, airflow, or any other internal issues that exist and need to be analyzed and repaired with care.

4. Ductwork Concerns

Ductwork leakages and blockage can drastically diminish the performance of your heat pump. Our Certified Technicians at Texas Strong Mechanical can professionally evaluate your ductwork, and detect and repair any problems that may be present to ensure proper airflow and system operation.

5. Persistent Heat Pump Problems

However, if you’ve already applied all the available remedies to your HVAC and the situation is still dire, you better make it a call to the experts at Texas Strong Mechanical, an AC repair company in Houston. A persistent use of a heat pump that keeps malfunctioning can worsen the situation and cause expensive repairs in the future. Our technicians have the expertise to analyze and correct even the most intricate heat pump issues.

Don’t just leave the performance of your heat pump at risk, but also that of your house and office or shop. Contact Texas Strong Mechanical in Houston, your top-rated HVAC contractor, whenever you run into situations that are beyond the realm of an average homeowner.

Maintaining Your Heat Pump for Peak Performance

Air Filter Replacements

Clogged air filters are responsible for one of the biggest factors affecting hose efficiency. Mark a calendar reminder to check and replace the filters every 1-3 months, depending on your consumption

Outdoor Unit Cleaning

Make sure the surrounding area of your outdoor unit is free from trash, foliage, and other blocks. With a garden hose, softly rinse the coil and fins being careful not to harm them during the process.

Professional Tune-Ups

At least once a year, make an appointment for a heat pump repair with Texas Strong Mechanical professionals. We’ll give a detailed examination, clean vital parts, verify the refrigerant level, and perform any necessary alterations to keep your heat pump working.

Timely Repairs

The maintenance should be wider than major pump problems only but also the small ones should be addressed.

Tackling issues immediately can avert the possibility of small problems growing and eventually resulting in large and costly repairs. If you identify, any strange acts or performance variations, no need to be alarmed, just reach us and we will quickly diagnose and repair it.

Why Choose Texas Strong Mechanical for Your Heat Pump Needs?

Being the top HVAC Houston company, Texas Strong Mechanical has the knowledge and experience to ensure that your heat pump is running at maximum efficiency.

Our professional technicians are subjected to ongoing training to stay informed on cutting-edge heat pump repair technologies and best practices. We are indeed proud to offer genuine, reliable, and affordable service whether it is a simple tune-up or an emergency fix.

By selecting Texas Strong Mechanical, you are assured that your heat pump system is in safe hands. Only the best parts and materials are used by us. Call us at Texas Strong Mechanical and we will be happy to help you in Houston with a top-performing, energy-saving heat pump system.