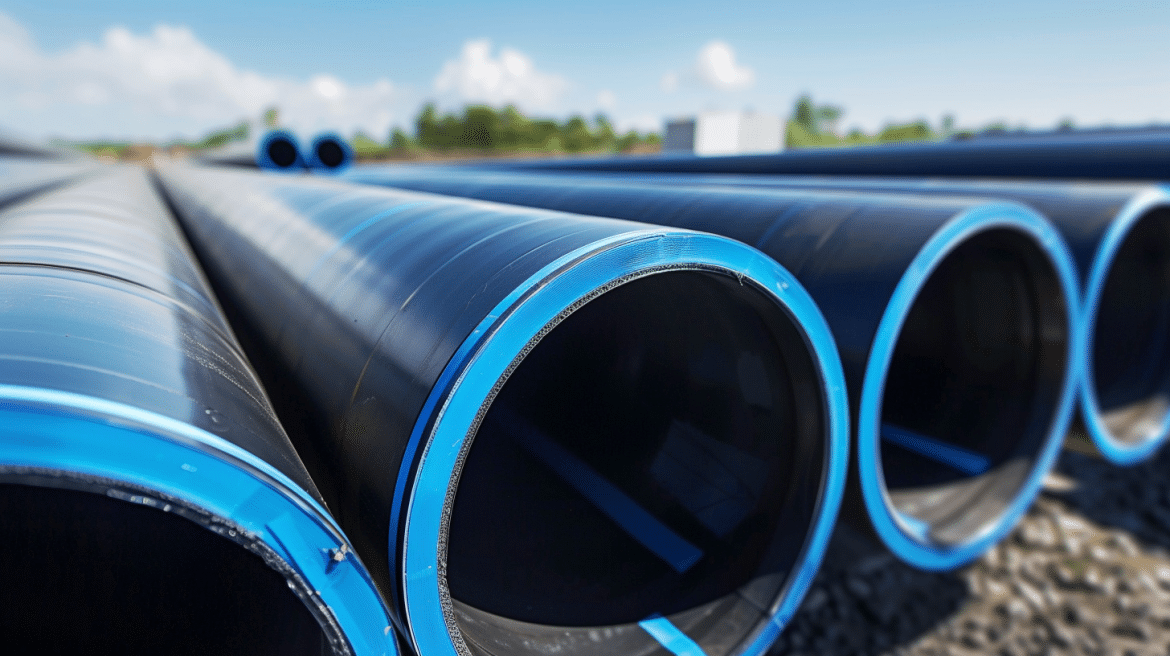

Within the framework of present-day water systems, the selection of pipe material greatly affects how water is efficiently and sustainably supplied and distributed. In this scenario, High-Density Polyethylene (HDPE) pipes have risen as an innovative solution that tackles the various issues presented by conventional pipe materials.

HDPE pipes have swiftly gained recognition in water infrastructure projects worldwide due to their outstanding combination of attributes.

1. Ability to Withstand Corrosion Damage: Preserving Water Quality and Infrastructure Integrity

Corrosion is when pipes slowly wear away because of chemicals in water and soil. HDPE pipes offer an exceptional advantage in this regard with their inherent corrosion resistance. Unlike traditional materials like steel or iron, they are immune to rust, scaling, and chemical reactions.

This resistance translates to improved water quality as contaminants from corroded pipes are kept at bay. When pipes don’t corrode, they last longer. This means less often changing and fixing them. These strong pipes keep water clean and infrastructure strong for a long time.

2. Durability: Withstanding the Test of Time and Pressure

Polyethylene pipes are really strong, so they work well in challenging water distribution systems. Being really good at resisting wear, abrasion, and impact, these pipes can handle extreme weather, soil changes, and pressure without a problem. Because of this durability, the pipes last longer and are less likely to leak or burst.

3. Flexibility: Conforming to Terrain and Minimizing Installation Problems

These water conduits are different because they can bend easily. Because of this flexibility, installing the pipes becomes easier as they can match the shape of the land. Unlike inflexible materials like PVC pipes fittings that need to be positioned precisely and have extra parts, these pipes can be easily moved around obstacles.

This reduces the need for a lot of digging and trenching. Also, because of this flexibility, absorbing ground movements and vibrations are more manageable. Therefore, reducing the chances of fractures or failures. This ability to adjust doesn’t only speed up installation. It also lessens disruptions to the environment around, which is why they’re considered environmentally friendly.

4. Ease of Installation: Streamlining Projects and Reducing Costs

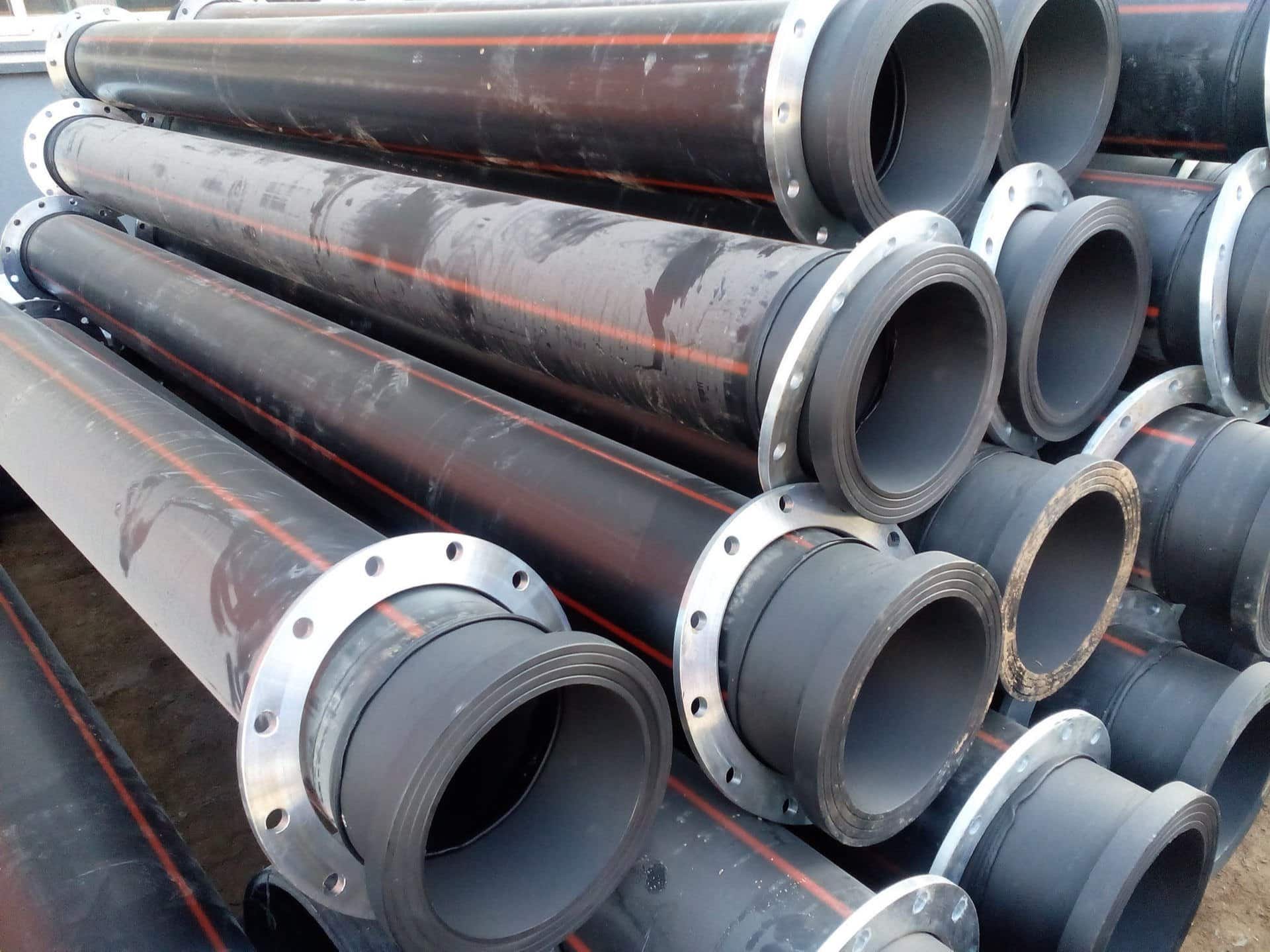

HDPE pipes are known for their user-friendly installation methods that often require fewer resources and less time compared to traditional materials. Processes like butt fusion and electrofusion enable efficient joining, doing away with the necessity for intricate welding or threading steps.

Because these pipes are lightweight, they’re easy to handle and move around. Because of this, labor and equipment expenses are cut down. Installing them quickly means projects finish sooner and don’t bother local communities as much. In the end, easy installation directly helps save money and improves the efficiency of water projects.

5. Reduced Maintenance Requirements: Ensuring Long-Term Sustainability

Polyethylene pipes bring advantages not just for installation but also for maintenance. Their resistance to corrosion and durability mean they experience very little wear and tear as time goes by. Thanks to this attribute, there is a notable reduction in the requirement for maintenance interventions, which translates into both time and resource savings.

These pipes do their job better because they stay safe from chemicals and keep away things that could grow on them. That means the water they provide is clean and trustworthy. Less maintenance work also fits with sustainability goals, because fewer replacements and repairs lead to using fewer materials and causing less harm to the environment.

6. Leak Resistance: Minimizing Water Loss and Operational Disruptions

These pipes are naturally good at resisting leaks because they have a uniform structure and seamless fusion joints. Unlike materials that require multiple fittings and connections prone to leaks, they offer a continuous pipeline with fewer opportunities for leakage points.

Apart from reducing losses, through water preservation, it also ensures a reliable water supply by avoiding unexpected leaks that could disturb operations. Not letting water leak out, these pipes show they’re vital for using water well and keeping it safe.

7. Chemical Resistance: Safeguarding Against Corrosive Substances

In scenarios where conveyed water may contain aggressive chemicals or pollutants, the chemical resistance of such pipes becomes a significant advantage. These pipes stay strong even when they’re exposed to different chemicals; they don’t degrade or become weaker.

This special part is very significant in factories, places that make dirty water clean, and areas where the water under the ground might be harmful. Because they stay strong and work well even in tough chemical conditions, these pipes keep water systems safe and working effectively.

To sum up, HDPE pipes begin a big shift in water systems, completely changing how water is used and moved. Their capacity to withstand corrosion, endure over time, bend easily, install smoothly, prevent leaks, and resist chemicals goes beyond just improving the efficiency and trustworthiness of water systems; it also aids in the sustainable management of vital resources.

While cities grow and the climate changes, picking these pipes shows new thinking. This might lead to a time when water systems are strong, not too costly, and friendly to the environment. Contrasting with standard materials like PVC pipe fittings, HDPE pipes provide an all-inclusive solution that caters to various needs of contemporary water infrastructure.